Asbestlint, often referred to as a form of asbestos tape, rope, or fibrous material, may sound like a technical term, but it’s something that still affects many older homes and workplaces. Used in the past for insulation, sealing, and fireproofing, asbestlint is now recognized as a serious health risk because of the tiny airborne fibers it can release. When disturbed, these fibers can cause long-term illnesses such as asbestosis, lung cancer, and mesothelioma. This article will help you understand what asbestlint is, why it’s dangerous, how to identify it, and most importantly, the safest way to handle or remove it.

What is Asbestlint?

The word asbestlint comes from combining “asbest” (asbestos) and “lint” (fibers, strips, or tape). In simple terms, it refers to asbestos-containing materials that appear in tape, rope, or fibrous lint-like forms. For decades, builders used asbestos tape and rope gaskets for sealing boilers, stoves, HVAC systems, and pipes because of their heat resistance and durability. Over time, however, these materials can break down and release friable asbestos fibers into the air. That makes asbestlint not just a construction leftover but a hidden danger in many older buildings. Understanding its forms and history is the first step in recognizing why safe handling and testing by licensed asbestos professionals is so important.

Common Uses of Asbestlint in the Past

Asbestlint was widely used during the mid-20th century when asbestos tape, rope, and insulation materials were considered reliable and affordable. Builders and manufacturers valued its heat resistance, fireproofing qualities, and strength, making it a go-to option for sealing joints, wrapping pipes and boilers, and insulating HVAC systems. Rope gaskets lined stoves, kilns, and furnaces, while asbestos tape secured fittings in electrical and mechanical equipment. In many factories and ships, asbestlint served as a protective barrier against extreme heat. Unfortunately, these same products are now recognized as asbestos-containing materials (ACMs) that can release dangerous airborne fibers when disturbed. Knowing these past uses helps homeowners, contractors, and inspectors identify where asbestlint might still exist in older buildings today.

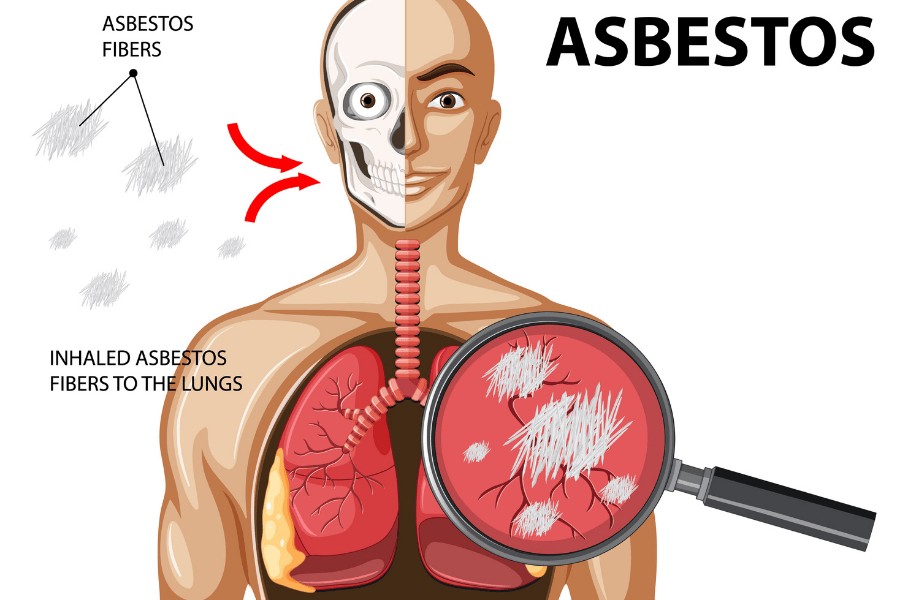

Why Asbestlint is Dangerous?

The biggest danger of asbestlint lies in its ability to release microscopic asbestos fibers when it becomes damaged or disturbed. These fibers are friable, meaning they easily break apart and float in the air, where they can be inhaled without notice. Once inside the lungs, asbestos fibers can cause long-term health problems such as asbestosis, lung cancer, and mesothelioma. The risk is even greater in older buildings where asbestos tape, rope, and insulation materials have deteriorated over time. Exposure doesn’t cause immediate symptoms; diseases often appear decades later, making prevention critical. This is why experts stress avoiding DIY removal and relying on licensed asbestos abatement professionals who can manage and safely contain the risks of asbestlint exposure.

Identifying Asbestlint

Spotting asbestlint isn’t always easy because it often looks like ordinary tape, rope, or fibrous insulation. In many older buildings, you might find it wrapped around pipes, boilers, or HVAC systems, or used as gaskets in stoves and furnaces. Common signs include brittle, gray-white tape or rope that appears dusty or lint-like. However, it’s important to remember that asbestos cannot be confirmed by sight alone. The safest way to identify asbestlint is through professional asbestos testing using accredited labs and methods such as PLM (Polarized Light Microscopy) or TEM (Transmission Electron Microscopy). Homeowners and contractors are advised not to disturb suspicious materials—doing so could release airborne asbestos fibers. Instead, treat any unknown material in older construction as potentially hazardous until tested.

How to Test for Asbestlint Safely

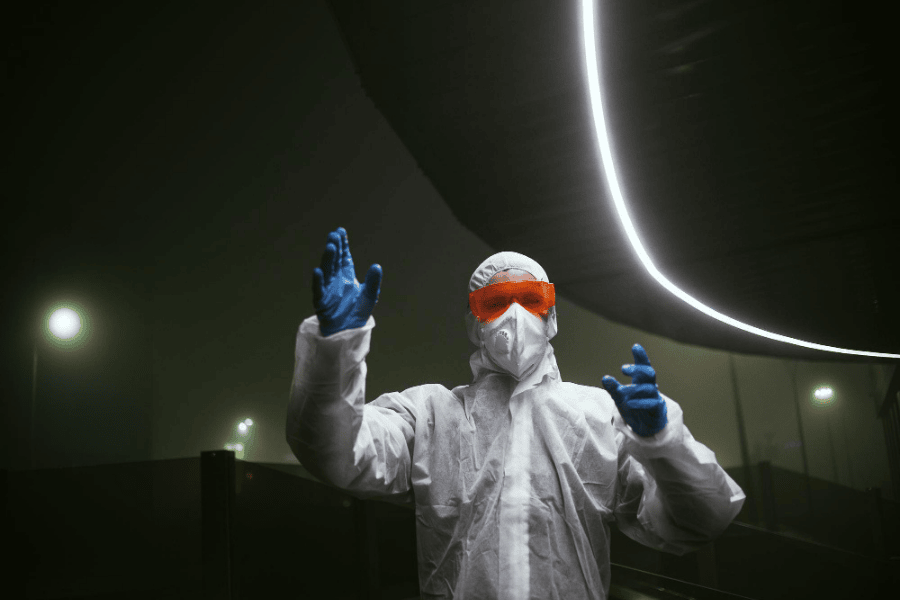

Testing asbestlint requires extreme caution because disturbing the material can release toxic asbestos fibers into the air. DIY kits exist, but experts strongly advise against sampling asbestos tape, rope, or insulation on your own. Instead, contact a licensed asbestos inspection professional who follows strict safety procedures. Certified inspectors use protective gear, HEPA filtration systems, and controlled sampling methods to prevent exposure. Collected samples are sent to accredited laboratories where techniques like PLM (Polarized Light Microscopy), TEM (Transmission Electron Microscopy), or PCM (Phase Contrast Microscopy) confirm the presence of asbestos. The process is usually quick, and results identify whether the material is a friable asbestos-containing material (ACM) that needs immediate attention. Hiring professionals not only protects your health but also ensures compliance with local asbestos regulations and disposal requirements.

Safe Handling & Management

When it comes to asbestlint, the number one rule is simple: do not disturb it. Even a small piece of damaged asbestos tape or rope gasket can release friable fibers that pose serious health risks. If you suspect asbestlint in your home or workplace, isolate the area and avoid sweeping, vacuuming, or touching the material. Professionals use specialized methods such as wet removal techniques, HEPA vacuums, and negative-pressure enclosures to safely manage and remove asbestos-containing materials. In some cases, encapsulation—sealing the asbestos fibers with a protective coating—may be safer than removal. Workers always wear proper PPE, including P100 respirators and disposable suits, to prevent exposure. Homeowners and contractors should never attempt DIY asbestos removal, as improper handling can contaminate an entire space. Instead, rely on licensed asbestos abatement services that follow strict disposal laws and clearance testing.

Legal & Regulatory Framework

Because asbestlint contains asbestos fibers, its handling and disposal are tightly regulated worldwide. Agencies such as the EPA (Environmental Protection Agency) in the U.S., OSHA (Occupational Safety and Health Administration), and the HSE (Health and Safety Executive) in the U.K. set strict rules for testing, removal, and waste management. Many countries have banned the use of asbestos tape, rope, and insulation materials, while others allow it only under controlled conditions. Contractors are required to follow asbestos abatement procedures, including using licensed professionals, maintaining a management plan, and ensuring proper air clearance testing after removal. Disposal must be carried out at approved hazardous waste facilities, with sealed packaging and documented chain of custody. For homeowners, understanding local asbestos laws is essential to avoid heavy fines and, more importantly, to protect community health. Always consult local regulations before starting any renovation involving potential asbestlint.

Modern Alternatives to Asbestlint

| Alternative | Type / Form | Max Service Temp (°C) Typical continuous |

Key Properties | Typical Applications | Pros | Considerations | Compliance Notes* |

|---|---|---|---|---|---|---|---|

| Fiberglass | Rope, tape, sleeving, cloth | ~540–600 | Good thermal insulation; low cost; abrasion-resistant | Pipe wraps, boiler doors, stove gaskets, expansion joints | Widely available; easy to handle; economical | Irritating fibers; not for >600 °C; needs proper end seals | Often available with ASTM E84, EN 13501-1 ratings |

| Ceramic Fiber | Rope, tape, blanket, modules | ~1100–1260 | Very high temperature capability; low thermal conductivity | Furnaces, kilns, boilers, exhaust shields | Handles extreme heat; lightweight | Can be brittle; respirable fibers—use PPE and follow handling guidance | Many products carry ASTM C892 / thermal classifications |

| Mineral Wool (Rock/Stone Wool) | Blankets, boards, pipe sections | ~650–800 | Non-combustible; good acoustic and thermal performance | HVAC ducting, pipe insulation, fire stops | Dimensionally stable; moisture-resistant binders available | Heavier than fiberglass; not for direct flame impingement | Commonly tested to ASTM E84, EN 13501-1 |

| Expanded Graphite (Flexible Graphite) | Sheet, tape, spiral-wound gasket filler | ~450 (oxidizing) / up to 3000 (inert) | Excellent sealing; chemical resistance; compressibility | Flange gaskets, valve/ pump packing, high-temp seals | High sealing integrity; wide chemical compatibility | Oxidizes at high temps in air; may need anti-oxidation inhibitors | Often meets API 607 fire-safe, TA-LUFT options |

| PTFE (High-Temp Grades) | Tape, sheet, envelope gaskets | ~260 | Low friction; excellent chemical resistance | Flange sealing in chemical, food, pharma services | Non-stick; clean; inert | Not for high-heat/flame; can creep—use structured/filled grades | Food-contact grades available (FDA); check pressure/temperature charts |

| Basalt Fiber | Rope, tape, fabric, sleeves | ~700–980 | High strength; good thermal resistance; low smoke | Exhaust wraps, furnace curtains, cable protection | More heat-tolerant than fiberglass | Less common than fiberglass; cost varies | Fire performance per supplier; some with E-mark / industrial ratings |

| Calcium Silicate | Boards, pipe coverings | ~650–1000 (grade-dependent) | Rigid, non-combustible, excellent structural insulation | Boiler/steam lines, refractory backing, fireproofing | High compressive strength; machinable | Brittle; dust during cutting—use controls and PPE | Fire-tested products widely available (EN 14306 types) |

| Fire-Rated Silicone Sealants | Sealant (cartridge/sausages), coatings | ~250–315 (short-term peaks) | Air-tight, flexible, smoke/fire-stop capability | Duct/penetration seals, appliance door seals (with rated kits) | Easy to apply; cures in place | Temperature limits; needs correct joint design & primers | Look for UL 1479, ASTM E814 fire-stop approvals |

| High-Temp Fiberglass Tapes (Vermiculite/Graphite Treated) | Tapes, ropes with coatings | ~600–700 | Enhanced heat & abrasion resistance; better sealing | Stove/kiln doors, expansion joints, boiler manways | Upgraded performance vs. standard fiberglass | Treatments can affect chemical compatibility—verify with media | Supplier fire/heat data; often ASTM E84 tested |

Compliance Notes: Standards vary by product and region. Always confirm current certifications, local code requirements, and manufacturer data sheets before selection. Temperatures shown are typical continuous ratings; check specific grade, atmosphere, pressure, and media.

Real-World Case Studies

Real examples show why asbestlint should never be ignored. In one renovation project, contractors discovered asbestos tape and rope gaskets hidden inside an old boiler system. Because the material was friable, they used licensed asbestos abatement professionals, sealed the area with negative-pressure enclosures, and safely removed the contaminated parts. Post-removal testing confirmed clean air quality, allowing the property to be safely reoccupied. In another case, improper DIY handling of asbestlint insulation in a residential attic caused widespread contamination. The cleanup cost tripled compared to a professional abatement, and the homeowner faced legal penalties for unsafe disposal. These stories highlight both the health dangers and the financial risks of mishandling asbestos-containing materials. The lesson is clear: only trained specialists with the right equipment should manage asbestlint exposure risks, ensuring safety, compliance, and peace of mind.

FAQs

Q: What is asbestlint made of?

A: Asbestlint refers to asbestos-containing materials such as tape, rope, or lint-like fibers once used for insulation and fireproofing.

Q: How do I know if I’ve been exposed?

A: Exposure to airborne asbestos fibers usually has no immediate symptoms. Illnesses like asbestosis, lung cancer, or mesothelioma can take decades to develop. If you suspect exposure, consult a healthcare professional.

Q: Can I remove asbestlint myself?

A: No. DIY removal is highly dangerous. Only licensed asbestos abatement professionals should handle or dispose of asbestos tape or rope.

Q: Where is asbestlint found?

A: It’s often found in older HVAC systems, boilers, pipe insulation, stoves, and kilns.

Q: How much does asbestos removal cost?

A: Costs vary depending on location, size, and risk level, but professional removal is always safer and more cost-effective long term.

Q: What are modern alternatives?

A: Today, fiberglass, ceramic fiber, mineral wool, and silicone sealants replace asbestos products safely and effectively.

Conclusion

Asbestlint, whether in the form of asbestos tape, rope, or fibrous insulation, may seem like a harmless leftover from the past, but its risks are very real. Once disturbed, it can release microscopic asbestos fibers that lead to life-threatening diseases such as asbestosis, lung cancer, and mesothelioma. The good news is that safe solutions exist. With modern asbestos regulations, professional abatement services, and reliable non-asbestos alternatives like fiberglass and ceramic fiber, we can protect our homes and workplaces. The most important step is awareness: never attempt DIY removal and always seek help from licensed asbestos professionals. By understanding asbestlint and managing it responsibly, you reduce health risks, avoid legal troubles, and create a safer environment for future generations.